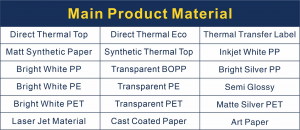

The materials of self-adhesive labels are divided into two categories

Paper: coated paper, writing paper, kraft paper, art texture paper, etc. Film: PP, PVC, PET, PE, etc.

Further expansion, the matte silver, bright silver, transparent, laser, etc. that we usually say are all based on the substrate or film made of film materials.

1. Paper labels (without lamination) are not waterproof and will break when torn. Generally, there are no special requirements, that is, coated paper is the most commonly used.

2. There is also a thermal paper label, which is also based on coated paper, with thermal materials added. The printing cost of thermal materials is low and no carbon ribbon is required. The disadvantage is that the printed handwriting is unstable and easy to fade, so it is used on some time-sensitive labels, such as express logistics labels, milk tea cups, supermarket price lists, etc.

3. Many people think that any waterproof label is PVC, but this is wrong. To be honest, PVC is not a common material. It has a strong smell and is not environmentally friendly. It is generally used in some outdoor applications, such as warning labels, mechanical equipment, etc. Its main attribute is durability. For safety and environmental protection, products such as food and daily chemicals will not use PVC materials.

4. Many people need to print after making labels, that is, they need to leave a blank part on the label and go back to print a part of the variable content. When making such labels, you must not laminate them. If you laminate them, the printing effect will not be good.

In this case, just use coated paper. Or synthetic paper made of PP

PP material is the most commonly used material in the current label industry. It is waterproof and cannot be torn. It also has the characteristics of paper and can be printed. It is very versatile.

5. Material hardness: PET > PP > PVC > PE

Transparency is also: PET > PP > PVC > PE

These four materials are often used in daily chemical cosmetics and other industries.

6. Label stickiness

Labels of the same surface material can also be customized to have various stickiness

For example, some labels need to be resistant to low temperatures, some need to be very sticky, and some need to be able to be torn off without leaving any residual glue after being pasted. All these can be done by manufacturers. If there is a ready-made file, it can be printed directly. If it is not designed well, the manufacturer can help design it.

Post time: Aug-20-2024